Working principle and use of valve positioner

A walk around a chemical plant is bound to see that some pipes are equipped with round-headed valves, which are regulating valves.

Pneumatic film regulating valve

The regulating valve can know some information from its name, and the key word adjustment is any adjustment between 0 and 100%.

Careful friends should find that there is a device hanging below the head of each regulating valve, familiar with sure know that this is the heart of the regulating valve, valve positioner, through this device can adjust the amount of gas into the head (pneumatic film), you can accurately control the position of the valve.

Valve positioners have intelligent positioners and mechanical positioners, and today we discuss the latter mechanical positioner, which is the same as the positioner shown in the picture.

The working principle of mechanical pneumatic valve positioner

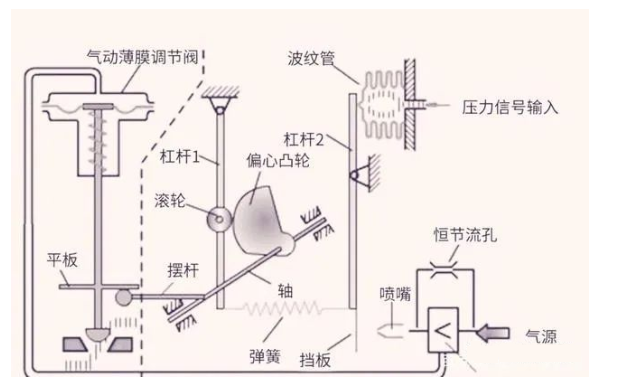

Valve locator structure schematic

In the figure, the components of the mechanical pneumatic valve positioner are basically said clearly, and the next step is to see how it works.

The air source comes from the compressed air of the air compressor station, and there is an air filter pressure reducing valve in the front section of the air source inlet of the valve positioner for the purification of compressed air. The air source from the pressure reducing valve outlet enters through the valve positioner, and how much gas enters the valve film head is determined according to the output signal of the controller.

The electrical signal output of the controller is 4 ~ 20mA, the pneumatic signal is 20Kpa~100Kpa, and the electrical signal is carried out from the electrical signal to the gas signal through the electrical converter.

When the electrical signal output by the controller is converted into the corresponding gas signal, the converted gas signal is then applied to the bellows. Lever 2 moves around the fulcrum, and the lower part of lever 2 moves to the right near the nozzle. The back pressure of the nozzle increases, and after being amplified by the pneumatic amplifier (the part with less than symbol in the figure), a part of the air source is sent to the air chamber of the pneumatic film, and the valve stem with the valve core downward automatically decreases the opening of the valve. At this time, the feedback rod connected to the valve stem (pendulum rod in the figure) moves down around the fulcrum, so that the front end of the shaft moves down, the eccentric CAM connected to it does counterclockwise rotation, and the roller rotates clockwise to the left, thus stretching the feedback spring. As the lower part of the feedback spring stretch lever 2 moves to the left, it will reach force balance with the signal pressure acting on the bellows, so the valve is fixed in a certain position.

Through the above introduction, we should have a certain understanding of the mechanical valve positioner, and when we have the opportunity to operate, it is best to be able to disassemble once, deepen the position of each part of the positioner and the name of each part. Therefore, the discussion of mechanical valves comes to an end, and the next step is to expand knowledge, so that the regulator has a deeper understanding.

Knowledge expansion

Knowledge extension one

The pneumatic film regulating valve in the figure belongs to the gas-closed type, and someone asked, why?

First, look at the air inlet direction of the pneumatic film, which is a positive effect.

Second, look at the spool installation direction, positive effect.

Pneumatic film air chamber air source, diaphragm pressure diaphragm covered six spring springs, thereby pushing the valve stem downward, the valve stem is connected with the spool, the spool is installed forward, so that the air source is the valve to move to the closed position. Therefore, it is called the gas shutoff valve. Failure means that when the gas supply is interrupted due to the corrosion of the construction or gas pipe, the valve is reset under the reaction force of the spring, and the valve is in the fully open position.

How to use the gas shutoff valve?

How to use it is considered from a safety point of view, which is a necessary condition for choosing gas to open or gas to close.

Give an example; One of the core devices of the boiler, the drum, a regulating valve for the water supply system must be air-closed. Why? For example, if the air source or power supply is suddenly interrupted, the furnace is still burning vigorously, constantly heating the water in the drum. If the gas opening regulating valve is used, the energy is interrupted, the valve is closed, and the drum does not enter the water for minutes to dry (dry burning), which is very dangerous, and it is impossible to deal with the regulating valve failure in a short time, which will lead to the furnace shutdown accident. Therefore, to avoid dry burning or even furnace shutdown accidents, it is necessary to use gas shut-off valve. Although the energy is interrupted, the regulating valve is located in the fully open position, and the drum is constantly flooded, it will not lead to the drum drying money, and there is still time to deal with the regulating valve failure without directly stopping the furnace.

Through the above example, we should now have a preliminary understanding of how to choose the gas open regulating valve and gas close regulating valve!

Knowledge extension II

This little knowledge about positioner positive and negative changes.

The regulating valve in the figure is positive. The eccentric CAM has two sides AB, A represents the front, B represents the side. In this case, the A side is facing out, and the B side is facing out. Therefore, changing the A direction in the figure to the B direction is a counter-acting mechanical valve positioner.

The actual picture in the figure is a positive valve positioner, and the controller output signal is 4-20mA. When 4mA, the corresponding gas signal is 20Kpa, and the regulating valve is fully open. When 20mA, the corresponding gas signal is 100Kpa, and the regulating valve is fully closed.

Mechanical valve positioners have both advantages and disadvantages

Advantages: Precise control.

Disadvantages: Due to the pneumatic control, an additional electrical conversion device is required if the position signal is to be fed back to the central control room.

Knowledge extension III

On a daily basis.

It is normal to have faults in the production process, it is part of the production process. But in order to maintain quality, to maintain safety, to maintain quantity you have to deal with problems in a timely manner and that's the value of staying in the company. Therefore, several fault phenomena will be encountered briefly:

First, the valve positioner output such as turtle speed.

Do not open the valve positioner front cover; Listen to the sound, see if the air source tube is cracked leading to leakage, which can be judged by the naked eye. And if the input chamber leaks sound by listening.

Open the valve positioner front cover; 1, whether the constant throttle hole is blocked 2, check the position of the baffle 3, check the elasticity of the feedback spring 4, disassemble the square to check the diaphragm.

Two, the valve positioner output boring

1, to see whether the air source pressure is in the specified range and whether the feedback rod has fallen off, this is the simplest step.

2, check whether the signal line is correctly connected (later problems are generally ignored)

3, there is nothing stuck between the coil and the armature

4. Check whether the matching position of nozzle and baffle is suitable

5, check the electromagnetic component coil

6, check the balance spring debugging position is reasonable

Subsequently, the input signal, but the output pressure does not change, the output is not up to the maximum value, etc., these failures are also daily failures will encounter here no more.

Knowledge extension IV

The stroke of the regulating valve is adjusted

In the production process, the use of the regulating valve for too long will lead to inaccurate travel, and there is always a large error in the open to a certain position.

The stroke is 0-100%, and the maximum point is selected for adjustment, which is 0, 25, 50, 75, 100, respectively, which is expressed as a percentage. In particular, when adjusting the mechanical valve positioner, it is necessary to clearly locate the position of the two manual components of the adjustment zero position and adjustment span inside the positioner.

Take the gas opening regulating valve as an example to adjust.

The first step; Zero adjustment, the control room or signal generator to give 4mA, the regulator should be fully closed, not fully closed for zero. Zero to complete the direct adjustment of 50% of this point, and the difference between the span adjustment, while noting that the feedback rod and the valve stem should be in a vertical state. After adjustment, 100% of this point is adjusted, and after adjustment, it is repeatedly adjusted from five points between 0 and 100% until the opening is accurate.

A closing statement; From mechanical positioner to intelligent positioner. From the perspective of science and technology, the rapid development of science and technology has reduced the labor intensity of frontline maintainers. Personally, I think that if I want to exercise my hands-on ability and learn technology, mechanical positioner is the best, especially for new instrument personnel. To put it bluntly, the intelligent locator will understand the words on the manual, the finger moves on the line, what the zero adjustment range, adjustment of all automatic adjustment, as long as where the silly waiting for it to finish playing on its own to sort out the scene and leave is. For the mechanical type, many parts need to be dismantled and repaired by themselves, which will improve the hands-on ability and make more impression on its internal structure.

Whether it is intelligent or non-intelligent, it is in a dominant position for the entire automated production process, once the "strike", the adjustment is impossible to talk about, and the automatic control loses its meaning.

EN

EN CN

CN